12Bar Sand Blast Rubber Hose

12Bar Sand Blast Rubber Hose

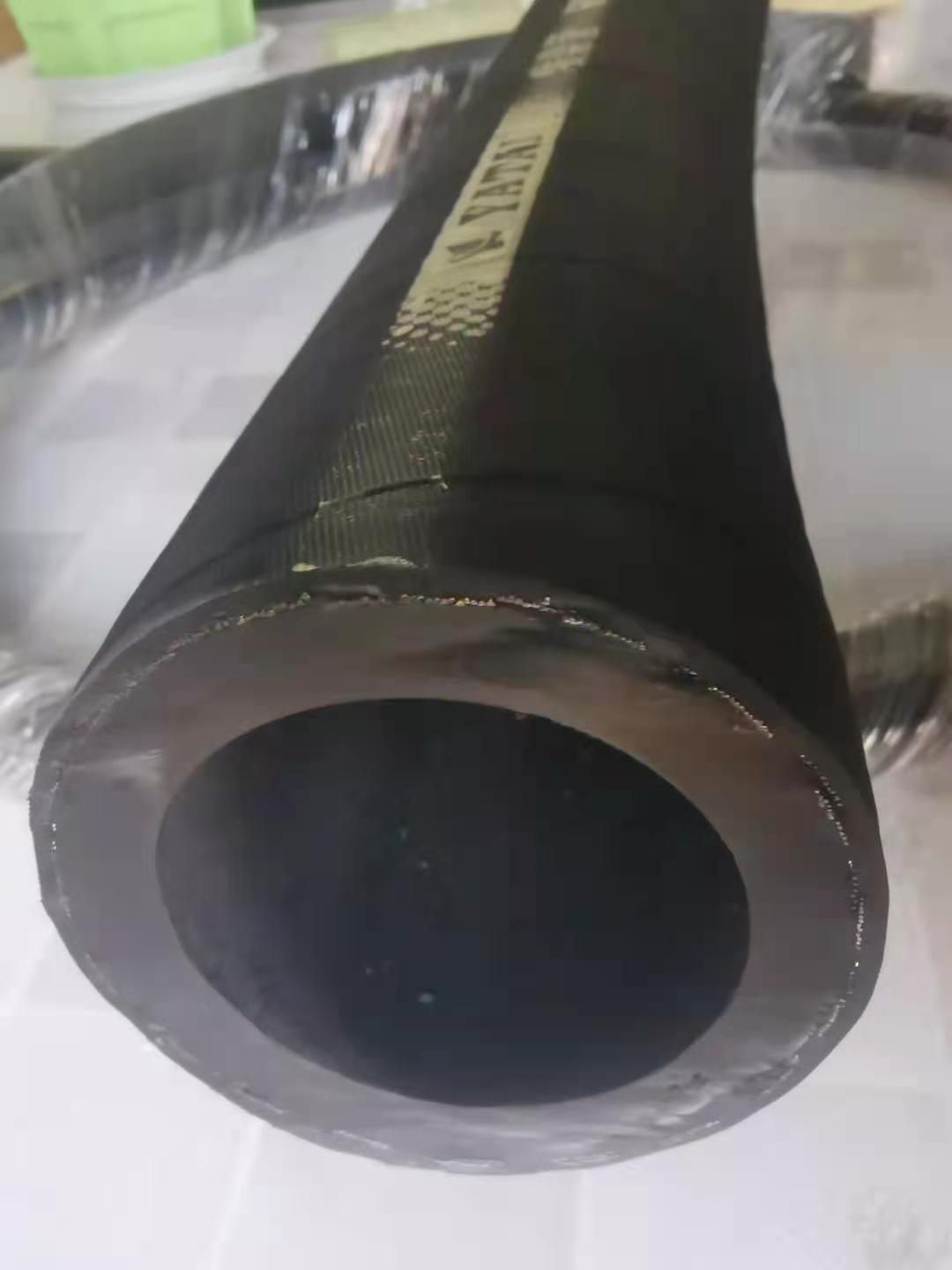

Tube: NR,BR,SBR

Reinforcement: High tensile textile cord with helix steel wire plus conductive copper wire

Cover: Weather and wear resistant NR, SBR

Standards: 12Bar

OEM: √

Product use:

Detail description:

Sandblasting pipe is a professional conveying pipe, which is widely used in many fields. Its unique design and high-quality materials make it very suitable for conveying quartz, metal sand, polishing materials, metal surface rust removal and injection cement and other media.

The main features of sandblasting pipe include wear resistance, pressure resistance, corrosion resistance, etc. It can effectively resist the erosion of high-speed sand particles and ensure the long-term stable operation of the pipeline. In addition, the sandblasting tube also has good antistatic performance to ensure that static electricity will not be generated during the conveying process and to avoid accidents caused by static electricity.

In general, with its excellent performance and diverse application scenarios, the sandblasting pipe has become an indispensable tool in many industries, providing stable and reliable transportation services for various sandblasting operations. Its length can be customized according to actual needs to meet different engineering needs.

|  |  |  |  |  |  | ||||

| Specifications | Outer diameter | Working pressure | Burst pressure | Bending radius | Length | Weight | ||||

| dash | inch | mm | mm | Bar | psi | Bar | psi | mm | m/roll | kg/m |

| -4 | 1/4" | 6.4 | 18.0 | 12 | 180 | 36 | 540 | 65 | 50-100 | 0.3 |

| -5 | 5/16" | 7.9 | 20.0 | 12 | 180 | 36 | 540 | 75 | 50-100 | 0.34 |

| -6 | 3/8" | 9.7 | 22.0 | 12 | 180 | 36 | 540 | 75 | 50-100 | 0.40 |

| -8 | 1/2" | 12.7 | 25.0 | 12 | 180 | 36 | 540 | 100 | 50-100 | 0.47 |

| -10 | 5/8" | 16.0 | 28.0 | 12 | 180 | 36 | 540 | 125 | 50-100 | 0.54 |

| -12 | 3/4" | 19.1 | 32.4 | 12 | 180 | 36 | 540 | 190 | 60 | 0.73 |

| -16 | 1" | 25.4 | 38.4 | 12 | 180 | 36 | 540 | 250 | 60 | 0.90 |

| -20 | 1.1/4" | 31.8 | 48.0 | 12 | 180 | 36 | 540 | 320 | 60 | 1.31 |

| -24 | 1.1/2" | 38.1 | 55.0 | 12 | 180 | 36 | 540 | 380 | 60 | 1.64 |

| -32 | 2" | 50.8 | 69.8 | 12 | 180 | 36 | 540 | 510 | 60 | 2.45 |

| -40 | 2.1/2" | 64 | 83.6 | 12 | 180 | 36 | 540 | 640 | 60 | 2.97 |

| -48 | 3" | 76 | 97.6 | 12 | 180 | 36 | 540 | 760 | 60 | 3.85 |

| -64 | 4" | 102 | 126.4 | 12 | 180 | 36 | 540 | 1020 | 60 | 5.74 |

Industry application:

The product manufacturing meets or exceeds the requirements of SAE, DIN, GB, GOST or other industries, and has the properties of high pressure resistance, high humidity resistance, softness, high pulse pressure, no head expansion, light weight, long life, etc. The main fields and equipment involved include ships, vehicles, construction machinery, mining, agriculture, construction, environmental protection, wind power, transportation, petroleum, electric power, food, chemical industry, metallurgy, injection molding, etc...