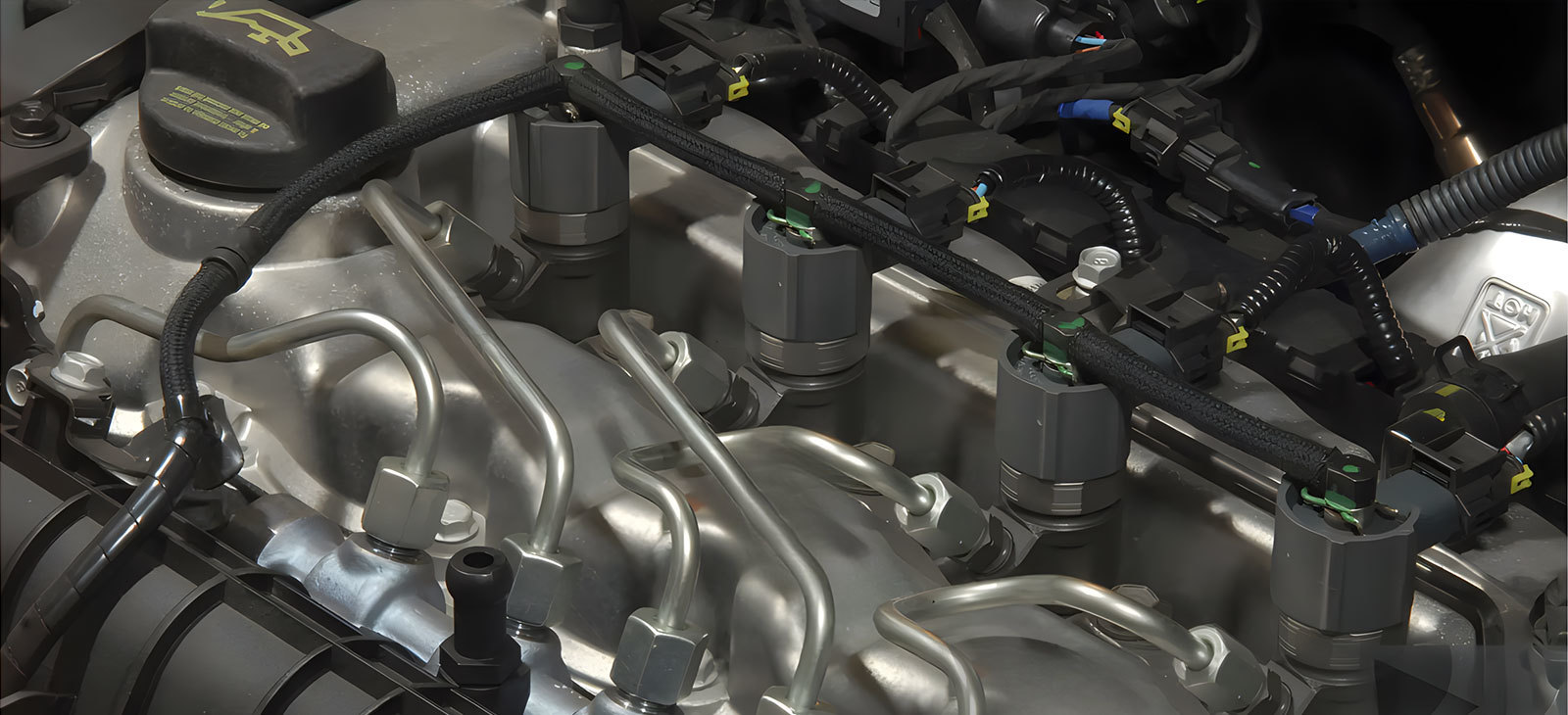

Fuel Injection Hose

SAE J30 R9/R10 Fuel Injection Hose

Barrier: FKM

Tube: NBR

Reinforcement: One layer aramid fiber braid

Cover: Weather and oil resistant CR

Standards: SAE J30 R9

OEM: √

Product use:

Detail description:

The fuel injection pipe is one of the key components of the engine, which is mainly used to control the fuel injection process to optimize the combustion efficiency. The precise design of the piping ensures precise and efficient injection of fuel into the engine combustion chamber. Its structure generally includes fuel injection nozzles, control valves and connecting oil pipes. Under high pressure, fuel is sprayed through the fuel injector to form a mist, which is mixed with air and burned to generate power. Fuel injection pipes are essential for improving engine performance, reducing emissions and increasing fuel economy. Its material and design must meet strict engineering standards to ensure stable operation of the engine under various operating conditions. The above is a brief introduction to the fuel injection pipe.

|  |  |  |  |  |  | ||||

| Specifications | Outer diameter | Working pressure | Burst pressure | Bending radius | Length | Weight | ||||

| dash | inch | mm | mm | Bar | psi | Bar | psi | mm | M/roll | kg/m |

| -2 | 5/32" | 4 | 9.1 | 35 | 500 | 140 | 2000 | 40 | 50-100 | 0.12 |

| -3 | 3/16" | 4.8 | 10.3 | 35 | 500 | 140 | 2000 | 40 | 50-100 | 0.15 |

| -4 | 1/4" | 6.4 | 13 | 28 | 400 | 112 | 1600 | 45 | 50-100 | 0.16 |

| -5 | 5/16" | 7.9 | 14.6 | 28 | 400 | 112 | 1600 | 65 | 50-100 | 0.19 |

| -6 | 3/8" | 9.7 | 16.5 | 28 | 400 | 112 | 1600 | 80 | 50-100 | 0.24 |

| -8 | 1/2" | 12.7 | 20.4 | 28 | 400 | 112 | 1600 | 100 | 50-100 | 0.32 |

| -10 | 5/8" | 16.0 | 23.6 | 24 | 350 | 96 | 1440 | 160 | 50 | 0.39 |

| -12 | 3/4" | 19.1 | 27.6 | 21 | 305 | 84 | 1218 | 190 | 50 | 0.52 |

| -14 | 7/8" | 22.0 | 31.0 | 20 | 300 | 80 | 1200 | 220 | 50 | 0.60 |

| -16 | 1" | 25.4 | 34.5 | 17.5 | 250 | 75 | 1000 | 250 | 50 | 0.66 |

Industry application:

The product manufacturing meets or exceeds the requirements of SAE, DIN, GB, GOST or other industries, and has the properties of high pressure resistance, high humidity resistance, softness, high pulse pressure, no head expansion, light weight, long life, etc. The main fields and equipment involved include ships, vehicles, construction machinery, mining, agriculture, construction, environmental protection, wind power, transportation, petroleum, electric power, food, chemical industry, metallurgy, injection molding, etc...