Full-Scenario Liquid Cooling Hoses, New Heat Dissipation Benchmark!

2026-01-14 | Company News

As AI large model training and high-density data centers become the norm, GPU power consumption has exceeded 700W, leaving traditional air cooling far behind. Liquid cooling technology stands at the core of the heat dissipation revolution, and liquid cooling hoses—acting as the "blood vessels" of the system—directly determine heat dissipation efficiency, stability, and long-term costs. Today, we’re unveiling a full-scenario liquid cooling hose solution with uncompromising performance!

Why Have Liquid Cooling Hoses Become a Must-Have for Computing Power Upgrades?

With the global liquid cooling market expected to surpass RMB 60 billion by 2025 and a penetration rate approaching 40%, liquid cooling hoses have evolved from "optional accessories" to "core necessities."

Heat Dissipation Efficiency Outperforms Air Cooling: The cooling fluid delivered by liquid cooling hoses has a much higher specific heat capacity than air, boosting heat dissipation efficiency by over 50% compared to air cooling. It easily handles high heat flux scenarios of 200W/cm².

Ultimate Energy Savings & Cost Reduction:Systems equipped with high-quality liquid cooling hoses can achieve a data center PUE as low as 1.05. A 10MW-level computer room saves over 2 million US dollars in annual electricity costs, and the total cost of ownership (TCO) over 5 years outperforms air cooling.

Full-Scenario Adaptability:From 100kW-level cabinets in supercomputing centers to compact edge computing devices and temperature control in energy storage systems, liquid cooling hoses deliver precise compatibility.

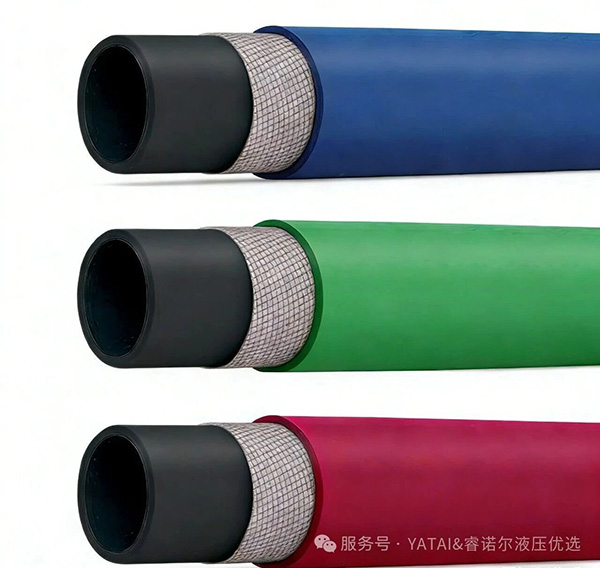

Four Core Liquid Cooling Hoses: Precision-Matched to Diverse Scenarios

With deep expertise in the liquid cooling hose sector, we’ve launched four core products tailored to different application needs, covering all operating conditions with distinct strengths:

1. Lined Rubber Hose: The Preferred Choice for Cleanliness & Practicality

Core Advantages

Inherits the flexibility and insulation of traditional rubber hoses, while adding a lining layer for clean, contamination-free fluid delivery—preventing coolant deterioration that impacts heat dissipation efficiency. It maintains a low cost, offering outstanding value for money.

Application Scenarios

Cooling systems for electronic devices and precision instruments requiring clean coolant, as well as scenarios balancing cost and practicality.

Key Specifications

Inner and outer rubber layers are made of CIIR (Chlorobutyl Rubber); the middle reinforcement layer is PET. The lining layer offers two options: PA12 Nylon (operating temperature: -55℃ to +150℃) or UHMWPE (Ultra-High Molecular Weight Polyethylene, operating temperature: -60℃ to +90℃), adapting to different temperature conditions.

2. CIIR Rubber Hose: Cost-Effective Entry-Level Option

Core Advantages

Retains the flexibility of traditional rubber hoses for easy bending and complex routing during installation; features inherent insulation for safe use. It is cost-friendly, ideal for bulk deployment. Core upgrade: CIIR material delivers 100x better impermeability than EPDM, effectively reducing coolant loss.

Application Scenarios

General water-cooled equipment, cost-sensitive bulk engineering projects, and water-based coolant applications.

Additional Core Advantages

Inherits the flexibility and insulation of rubber hoses; maintains low cost with excellent cost-performance.

Additional Application Scenarios

Cooling systems for electronic devices and precision instruments, balancing cost and practicality.

3. PTFE Hose: Benchmark for Longevity & Durability

Core Advantages

Exceptionally long service life for stable operation without frequent replacement; non-flammable with high safety; ensures clean, residue-free fluid delivery without contaminating coolants, suitable for harsh operating conditions.

Application Scenarios

Industrial equipment and high-end precision instruments requiring high temperature, high pressure, safety, and long service life.

Notes

Moderate flexibility—reserve sufficient routing space during installation; non-insulating—requires additional insulation protection; relatively high cost, ideal for core critical equipment.

4. Stainless Steel Metal Hose: Champion for Extreme Conditions

Core Advantages

Ultra-long service life with strong corrosion and aging resistance; non-flammable, clean fluid delivery, and resistance to harsh environments, compatible with various complex coolants.

Application Scenarios

Extreme conditions (high temperature, high pressure, strong corrosion), heavy industrial equipment, and cooling systems in outdoor harsh environments.

Notes

Low flexibility—route at fixed angles during installation; non-insulating—requires proper insulation treatment; prone to resonance during operation—install shock absorption devices.

Choose the Right Hose for Hassle-Free Heat Dissipation

The core of liquid cooling lies in "adaptability." Different scenarios demand varying flexibility, cleanliness, temperature resistance, and cost requirements. Selecting a liquid cooling hose tailored to your needs ensures stable heat dissipation, longer equipment life, and lower operational costs.Whether for general engineering projects, precision instrument cooling, or extreme condition applications, we provide accurate selection advice. Consult now to get a free customization plan—tailored to your actual operating conditions, coolant type, and temperature range—maximizing the value of every investment!For detailed specifications such as nominal inner diameter and outer diameter, or to request sample testing, feel free to leave a message for further communication!

联系人:李松 联系电话:18803088160 #液冷系统管#液冷